English

English

Jabra Sanitary is a sanitaryware supplier offering toilets, sinks, faucets, bathtubs, etc., at competitive prices. If you're a distributor, wholesaler, or project contractor, get a quote today!

$23.9 Limited-time Offer

$23.9 Limited-time Offer Consignment Policy

Consignment Policy 20 Years of Experience

20 Years of Experience

Toilets are an essential fixture in every home. While we use them daily, most of us don't give much thought to the toilet bowl parts that make them work.

However, understanding the inner workings of a toilet bowl and the toilet components can help you troubleshoot issues, perform maintenance, and even choose the right toilet.

In this article, we will break down the key parts of a toilet, explain how each part works, and offer practical tips for maintaining them.

Table of Contents

Why You Should Take Time to Learn Toilet Bowl Parts

Toilet Tank Parts

1. Toilet Tank

2. Toilet Flush Handle or Two Flush Buttons

3. Toilet Supply Line

4. Toilet Chain

5. Toilet Flapper

6. Toilet Float

7. Toilet Flush Valve

8. Toilet Fill Valve

9. Toilet Overflow Tube

10. Toilet Tank Cover

Toilet Bowl Parts

1. Elongated and Round Toilet Bowl

2. Toilet Tank O-Ring Seal/Toilet Gasket

3. Toilet Wax Ring

4. Toilet Seat

5. Toilet Bolts

6. Toilet Covers

7. Toilet Flange

Maintenance Tips for The Parts of a Toilet

Frequently Asked Questions about Toilet Spare Parts

Final Thoughts

Why You Should Take Time to Learn Toilet Bowl Parts

Understanding the various parts of a toilet bowl may not seem a priority at first glance. Still, it offers several practical benefits for homeowners, renters, and even professionals in the plumbing industry.

Here are some compelling reasons why taking the time to familiarize yourself with toilet bowl parts is a valuable investment of your time:

Empowers You to Troubleshoot Common Issues

Toilets are prone to a variety of issues, such as clogs, leaks, and flushing malfunctions. Knowing the components—like the flapper, fill valve, or flush handle—helps you quickly diagnose the root cause of a problem.

Reduces Repair Costs

Plumbing services can be expensive, especially for seemingly minor issues. By identifying and addressing problems by yourself, such as replacing a worn-out fill valve or adjusting a float, you can avoid costly service calls.

Learning these WC parts enables you to handle basic repairs and maintain your toilet without professional intervention.

Improves Maintenance and Longevity

Regular maintenance is key to ensuring your toilet operates efficiently over time. By understanding how toilet components like the tramway or wax seal function, you can perform periodic inspections to prevent wear and tear.

This knowledge also allows you to replace parts before they lead to more significant issues.

Helps You Make Informed Purchasing Decisions

When shopping for a new toilet or replacement parts, knowing the anatomy of a toilet bowl can help you select models that suit your needs.

You'll also understand the terminology used in product descriptions, such as “dual-flush system” or “gravity-feed design”, for the best fit for your household.

Boosts Environmental Awareness

Modern toilets come with water-saving features. Understanding the toilet components allows you to make environmentally conscious decisions. For example, dual-flush toilets use different mechanisms for liquid and solid waste disposal.

Recognizing these features ensures proper operation and maximizes efficiency.

By learning about toilet bowl parts, you not only enhance your repair skills but also contribute to a more sustainable and cost-effective household. Whether you're fixing a minor issue or upgrading your bathroom fixtures, this knowledge will empower you to take control of your plumbing needs.

Toilet Tank Parts

The toilet tank is an essential component of the toilet system, housing several important parts to ensure proper flushing and refilling.

Below, we break down toilet tank parts, how they work, and tips for fixing common issues.

1. Toilet Tank

The toilet tank is the main reservoir that holds water used for flushing. It is typically made of ceramic and is designed to store a precise amount of water, ensuring an effective flush.

The tank also houses various internal mechanisms that work together to regulate water flow and flushing.

How Does a Toilet Tank Work

The toilet tank stores the water required for flushing. When you activate the flush handle or button, the tank releases water into the bowl via the flush valve.

Afterward, the fill valve refills the tank to prepare it for the next use.

2. Toilet Flush Handle or Two Flush Buttons

A toilet flush handle is usually located on the side or front of the tank. It is a lever that lifts the toilet chain inside the tank.

Two flush buttons found on modern dual flush toilets allow users to choose between a partial or full flush. They conserve water for liquid or solid waste.

How Does a Flush Handle Work

The flush handle is connected to a lever inside the tank, which pulls the toilet chain to lift the flapper. Dual-flush systems use buttons to achieve a similar result, offering a lighter flush for liquids and a full flush for solids.

How to Fix a Toilet Handle

If your handle feels loose or doesn't work, check the connection to the lever. Tighten any loose nuts or replace a worn-out lever. If the handle is broken, you may need to replace it entirely, ensuring compatibility with your tank.

3. Toilet Supply Line

The supply line is a flexible pipe that connects the home's water supply to the toilet tank. It ensures the tank is refilled with water after each flush.

It includes a shutoff valve, which allows you to control or stop the water flow during repairs or emergencies.

How to Fix a Toilet Water Supply Line

The supply line connects the toilet tank to the water supply. If it leaks, check for loose connections or damaged washers. Tighten the nuts or replace the supply line if necessary, ensuring you shut off the water before making repairs.

4. Toilet Chain

The toilet chain is a small and adjustable link that connects the flush handle to the flapper. When you press the handle or button, the chain pulls the flapper open, allowing water to flow from the tank into the toilet bowl.

Proper chain tension is essential to avoid weak flushes or water leaks.

How to Fix a Toilet Chain

The toilet chain connects the flush lever to the flapper. If it's too loose or tight, adjust the chain length to allow smooth operation. Replace the chain if it's broken or rusted.

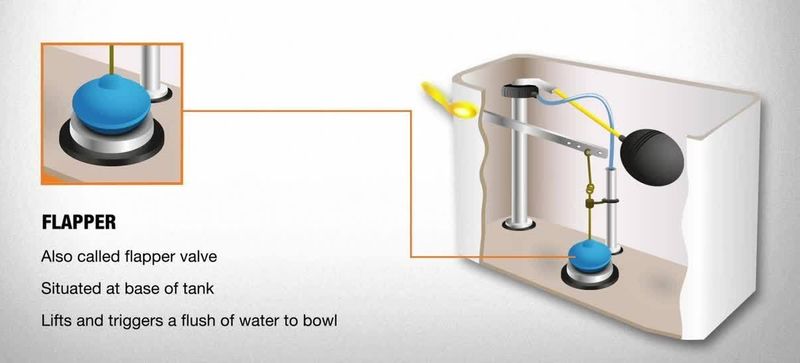

5. Toilet Flapper

The flapper is a rubber or plastic valve located at the bottom of the tank. It controls the release of water during a flush by sealing the flush valve opening. A damaged or worn-out flapper can cause water leaks or flushing issues.

How to Fix a Toilet Flapper Valve

The flapper controls the release of water during a flush. If your toilet runs continuously, the flapper might not seal properly. Replace the flapper if it's warped or degraded.

Ensure you make a flapper compatible with your toilet model.

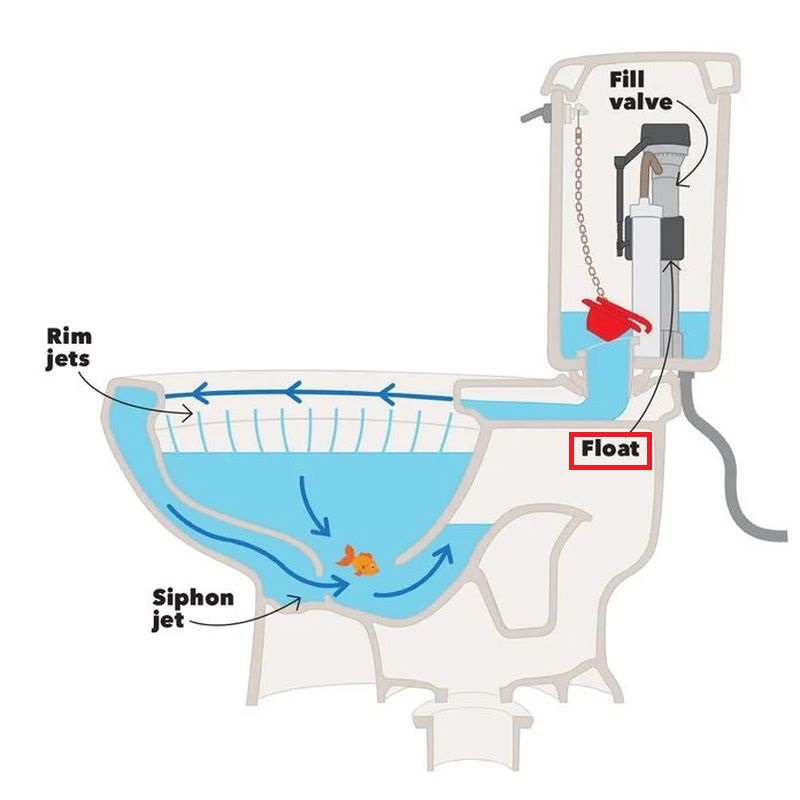

6. Toilet Float

The float is a buoyant device that controls the water level in the tank. As the tank refills after a flush, the float rises and shuts off the water supply once the optimal water level is reached.

Improper float adjustments can cause overflows or insufficient flushing.

How to Fix a Toilet Float

The float regulates the water level in the tank. If the tank overfills, adjust the float height using the screw or clip on the float arm. If the float is damaged, replace it to prevent leaks.

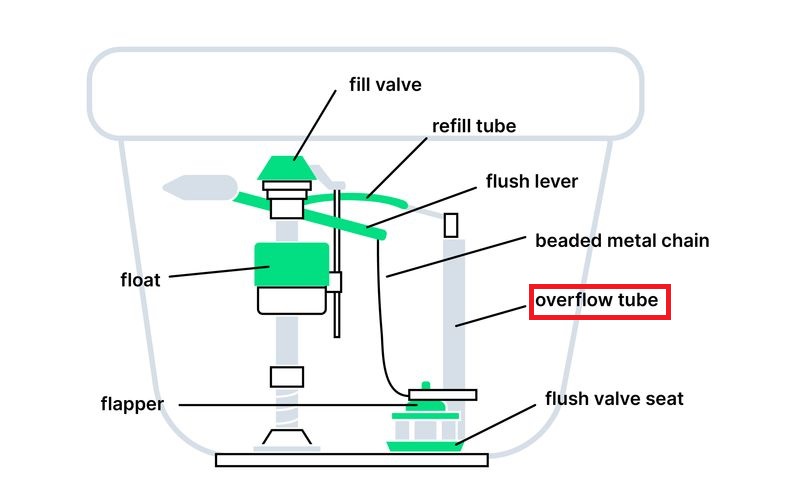

7. Toilet Flush Valve

The flush valve is a key toilet component that sits beneath the flapper. When the flapper lifts, the flush valve directs water from the tank into the toilet bowl with enough force to clear waste.

A malfunctioning flush valve may result in weak or incomplete flushes.

How to Fix a Toilet Flush Valve

The flush valve allows water to flow from the tank into the bowl. If it leaks or malfunctions, remove the tank to access the valve. Replace the valve if it's damaged, ensuring proper alignment and sealing during installation.

8. Toilet Fill Valve

The fill valve is responsible for refilling the toilet tank with water after each flush. It works in conjunction with the float to regulate the water flow.

Modern fill valves are adjustable, allowing users to control the water level and prevent overfilling.

How to Fix a Toilet Fill Valve

The fill valve controls the water flow into the tank after a flush. If the tank doesn't refill or overfill, clean the valve's filter for blockages or replace the valve if it's worn out.

9. Toilet Overflow Tube

The overflow tube is a vertical pipe inside the tank that prevents water from spilling out. Excess water flows through the tube directly into the toilet bowl, acting as a safeguard against overflows.

How to Fix a Toilet Overflow Tube

The overflow tube prevents the tank from overfilling by directing excess water into the bowl. If it's cracked or damaged, replace it to maintain proper tank operation.

10. Toilet Tank Cover

The tank cover is a ceramic or plastic lid that rests on top of the toilet tank. It protects the internal toilet components from dust, debris, and damage while maintaining the toilet's aesthetic appeal.

If the tank cover breaks, it should be replaced to prevent contamination or damage to the internal mechanisms.

What to Do If You Break the Toilet Tank Cover

A broken tank cover can be replaced with a new one from your toilet's manufacturer. If an exact match isn't available, opt for a universal cover that fits your tank dimensions. Handle tank covers carefully to avoid future breakage.

Toilet Bowl Parts

The toilet bowl is not just a simple ceramic structure. It consists of several toilet bowl parts names that ensure smooth waste disposal and user comfort.

Below, we explore these components, their functions, and tips for fixing common issues.

1. Elongated and Round Toilet Bowl

Toilet bowls come in two common shapes:

- Elongated Bowl: Oval-shaped, more comfortable, and ideal for larger bathrooms.

- Round Bowl: Compact and space-efficient, often used in smaller bathrooms.

How to Fix a Toilet Bowl

Toilet bowls can come in two common shapes: elongated for added comfort and round for saving space.

Fixing issues with a toilet bowl typically involves addressing cracks or leaks. For cracks, use a waterproof epoxy for minor repairs or replace the bowl if the damage is significant. For leaks, ensure the connections with the wax ring and flange are secure.

2. Toilet Tank O-Ring Seal/Toilet Gasket

The O-ring seal (or gasket) sits between the tank and bowl. It helps prevent leaks by creating a tight seal. It may need replacement over time.

How to Fix a Toilet Tank O-Ring Seal or Gasket

The O-ring or gasket seals the connection between the toilet tank and the bowl. If water leaks from this area, drain the tank, remove the bolts securing it, and replace the gasket with a new one.

Reattach the tank, ensuring all bolts are tightened evenly.

3. Toilet Wax Ring

A wax ring is placed between the toilet base and flange to create a watertight seal, preventing leaks from the waste pipe.

How to Fix a Toilet Wax Ring

The wax ring creates a watertight seal between the toilet base and the flange. If you notice water pooling around the toilet, the wax ring might be compromised.

Remove the toilet, scrape off the old wax, and install a new wax ring before reseating the toilet securely.

4. Toilet Seat

The seat cover is for sitting and the lid closes the bowl, containing odors and preventing objects from falling in.

How to Fix a Loose Toilet Seat

If your toilet seat cover becomes loose or breaks, inspect the hinges and bolts. Tighten or replace the bolts if necessary. If the bolts are stripped or damaged, replace them with new ones.

For a wobbling seat, use rubber washers for additional stability. For broken covers, purchase a replacement that matches your toilet model and install it following the manufacturer's instructions.

5. Toilet Bolts

Toilet bolts secure the toilet to the floor by fastening the toilet base to the flange. Loose or corroded bolts can cause instability or leaks.

How to Fix a Toilet Leaking From Tank Bolts

Tank bolts secure the toilet tank to the bowl. If they're loose or corroded, water may leak. Drain the tank, remove the bolts, and replace them with new ones.

Use rubber washers to ensure a watertight seal before reassembling.

6. Toilet Flange

The toilet flange connects the toilet to the floor and drain pipe. It ensures a secure fit and proper waste disposal with the wax ring in place.

How to Fix a Toilet Floor Flange

The toilet flange connects the toilet to the drainpipe. If it's damaged, it can cause leaks or a wobbly toilet. Remove the toilet and inspect the flange. Replace it with a new one if it's cracked or corroded.

Use a flange repair kit for minor damages, ensuring the new flange is level before reinstalling the toilet.

Maintenance Tips for The Parts of a Toilet

Proper maintenance of parts of a toilet is essential for ensuring longevity, optimal performance, and minimizing water waste.

Below are detailed maintenance tips for each part of a toilet:

Regular Cleaning and Inspection

- Toilet Bowl: Use a non-abrasive cleaner and toilet brush to clean the bowl weekly. It can prevent the buildup of limescale, stains, and bacteria.

- Tank Components: Inspect the toilet tank for mineral deposits and clean them regularly to ensure parts like the flapper and fill valve function properly.

- Exterior Parts: Wipe the exterior of the bowl, tank, and seat with a mild disinfectant to maintain hygiene and prevent grime accumulation.

Tighten Loose Connections

Check for loose connections in:

- Toilet Seat Bolts: Tighten the bolts to avoid a wobbling seat.

- Tank Bolts: Regularly inspect and tighten the tank bolts to prevent leaks.

- Water Supply Line: Ensure the supply line is properly secured to avoid water drips.

Replace Worn-Out Components

Over time, some toilet parts may wear out and need replacement.

Here's what to look out for:

- Flapper Valve: Replace if the toilet is constantly running or if the flapper doesn't seal properly.

- Wax Ring: If you notice water leaks around the base, it's time to replace the wax ring.

- Toilet Float and Fill Valve: Replace these toilet parts in the tank if the tank doesn't refill correctly or overflows.

Prevent Mineral Deposits

In areas with hard water, mineral deposits can clog and damage parts like the fill valve, flush valve, and flapper.

Use the following tips:

- Add a water softener or descaling agent to reduce mineral buildup.

- Soak removable parts like the flapper in vinegar periodically to dissolve deposits.

Check for Leaks Regularly

Leaking toilets can waste significant amounts of water. Perform these checks:

- Add a few drops of food coloring to the tank and wait for 10 minutes without flushing. If the color appears in the bowl, the flapper might be leaking.

- Inspect the floor around the base of the toilet for pooling water. The pooling water indicates a damaged wax ring or loose flange.

Lubricate Moving Parts

Lubricate the toilet handle, flush valve, and chain using a non-corrosive lubricant. It can ensure smooth operation and prevent rust or stiffness.

Protect the Tank Cover and Seat

- Tank Cover: Avoid placing heavy items on the tank cover to prevent cracks or breakage.

- Toilet Seat: Periodically tighten the seat bolts and check for wear on the hinges to maintain stability and usability.

Perform a Monthly Flush Test

Flush the toilet and monitor how the parts work together. Look for delayed flushing, unusual noises, or irregular water flow. Early detection of issues can save you from costly repairs.

Keep a Repair Kit Handy

Invest in a basic toilet repair kit that includes a replacement flapper, bolts, and washers. Having these items on hand can simplify minor fixes.

Professional Maintenance

While DIY fixes can solve most issues, schedule an annual inspection by a plumber to check for hidden problems, such as deteriorating pipes or damaged connections.

Frequently Asked Questions about Toilet Spare Parts

When it comes to toilet maintenance and repair, certain questions frequently arise. Below, we address these common queries to help you better understand how to manage your wc parts and functionality.

What toilet repair is the most common?

The most common toilet problems is a running toilet, usually caused by a faulty flapper.

Over time, the flapper may wear out or fail to seal properly, allowing water to continuously flow from the tank to the bowl. Replacing the flapper is a quick and cost-effective fix.

What is the main purpose of a P-trap?

The P-trap, a U-shaped pipe beneath the toilet, prevents sewer gases from entering your home by maintaining a water barrier. This essential toilet component also helps trap small objects accidentally flushed down the toilet, preventing them from entering the plumbing system.

What affects the water level in the toilet bowl?

The water level is regulated by the toilet's float and fill valve. A damaged or improperly adjusted float can cause the bowl to have too much or too little water. Adjusting or replacing the float usually resolves this issue. Learn how to correct water level in toilet bowl.

How to make your toilet more water-efficient?

Install a dual-flush mechanism or use a low-flow toilet model. Additionally, regularly check for leaks and repair them promptly to prevent water wastage.

How often should you replace toilet parts?

Most parts of a toilet, such as a flapper, fill valve and wax ring, should be inspected annually and replaced every 3-5 years.

How do I know when my toilet flapper needs replacing?

If your toilet is constantly running, the flapper might be the culprit. Check for visible wear, cracks, or improper sealing. Replacing the flapper typically resolves the issue.

Final Thoughts

Understanding the various toilet bowl and tank parts and how they function is essential for maintaining a well-operating bathroom.

Regular inspections, timely repairs, and preventive maintenance can save you from costly plumbing emergencies. A well-maintained toilet ensures comfort, hygiene, and peace of mind for your household.

If you still have any questions such as toilet components names and how to replace toilet parts by yourself, please feel free to contact Jabra Sanitary!