English

English

4-Step Quality Management System at Jabra Sanitary

Only From Reliable Suppliers!

We only work with trusted suppliers, some for more than 10 years.

We choose them for good quality, not just low price.

Our QC team checks every batch of materials carefully.

Only Premium Raw Materials Here!

We use precise raw materials proportions to ensure

the long-lasting durability of our toilets.

| Basic Raw Material | ||

|---|---|---|

| Material | Standard Range | Our Products Range |

| Copper | 58.63% | 58.50% |

| Lead | 0.5-2.5% | 1.5-2% |

| Tin | 0.0-1.0% | 0.1-0.3% |

| Nickel | 0.0-1.0% | 0.3-0.5% |

| Iron | 0.0-0.8% | 0.5-0.7% |

| Aluminum | 0.0-0.8% | 0.7-0.9% |

| Manganese | 0.0-0.5% | 0.08-0.09% |

| Zinc | Balance | Balance |

| Nickel Chromium Thickness | |

|---|---|

| Physical Properties | Observed Range |

| Shore Hardness “A” | 60-90 |

| Tensile Strength (Kgf/CM2) | 160-180 |

| Elongation (%) | 370-400 |

| Specific Gravity | 1.15-1.28 |

| Compression Set (%) | 17-23 |

| Nickel Chromium Thickness | ||

|---|---|---|

| Particulars | As per Standard | Our Products |

| Nickel 10 Micron | 10 Micron | 12 to 15 Micron |

| Chromium | 0.3 Micron | 0.5 to 0.7 Micron |

100% Quality Control

Jabra Sanitary does 100% product inspection for each item before delivery to

make sure it's perfect.

Any faulty item is either fixed or replaced quickly.

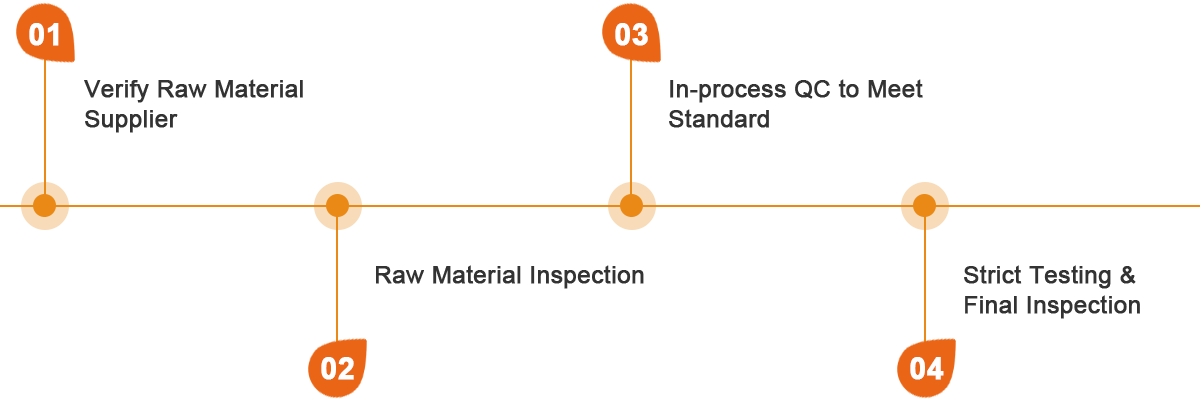

01

In-process QC

Our QC team inspects each item daily including wet-dry porcelain inspection. And check the appearance to see if there are air bubbles, pinholes, or cracks.

02

Semi-finished Product Testing

Workers will carry out various tests to test functions, including visual inspection, flushing tests, water absorption, chemicals, crazing resistance, resistance to staining and burning, etc.

03

Final Inspection

We ensure a final QC inspection of all finished product details before packing, focusing on uniform color, shape, smooth glazing, and standard physical properties.

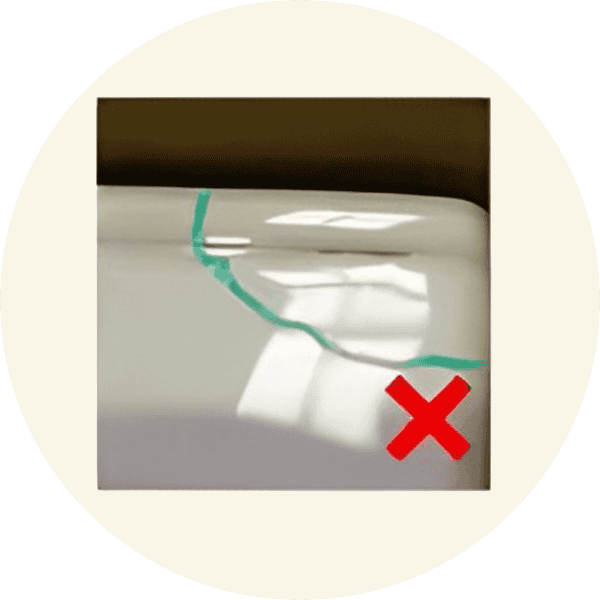

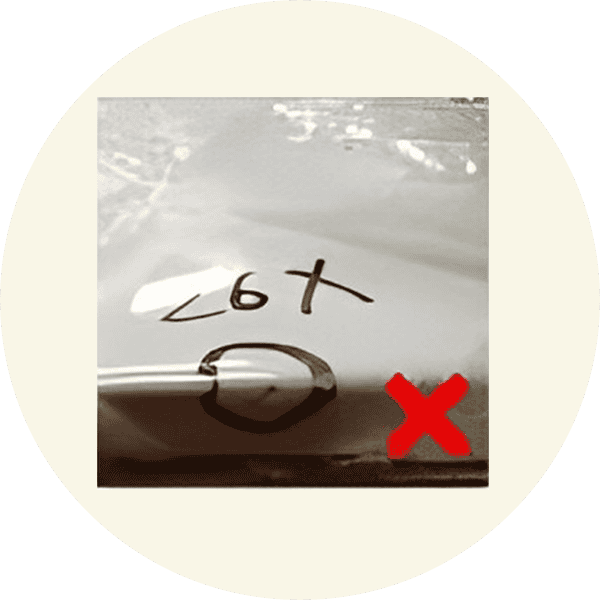

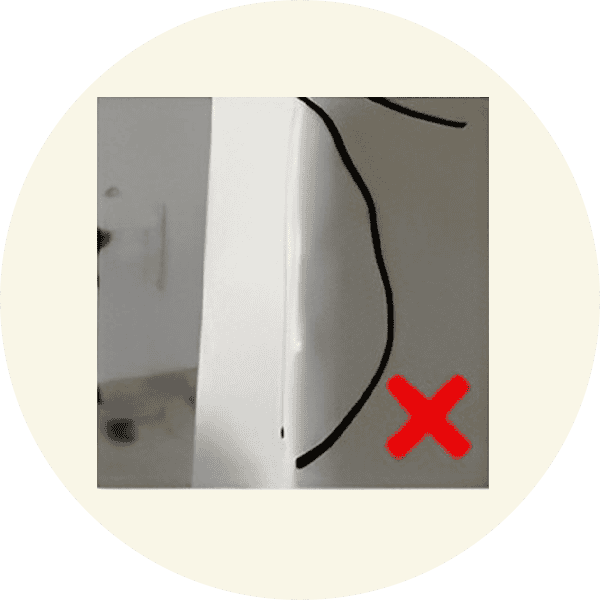

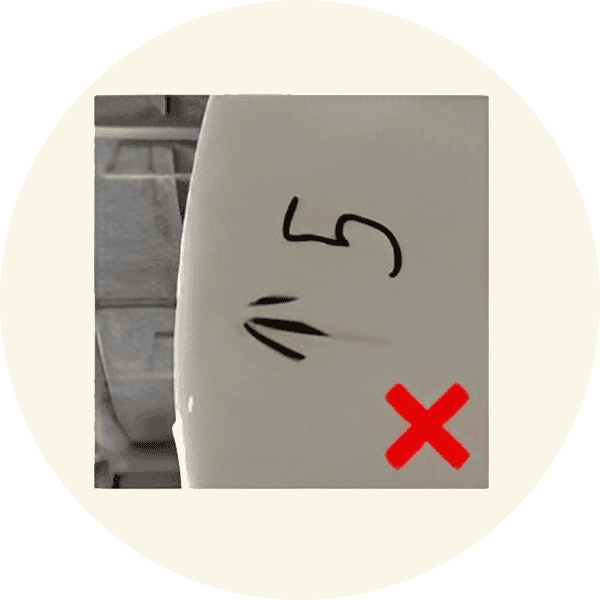

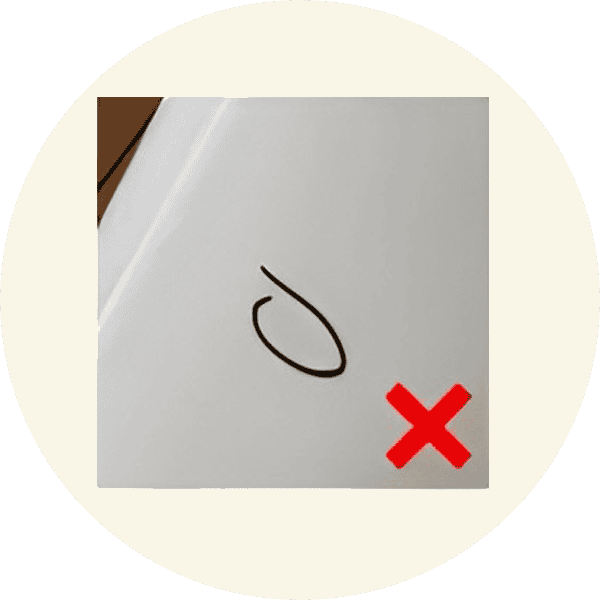

Rejected Items

Our QC team rigorously inspects all items against international standards,

rejecting any with even minor defects without exception.

Crack

Big Pinhole

Glaze Bubble

Different Color

Pores

Speck

| Appearance Standard Form | |||

|---|---|---|---|

| Defect Type | Face A (Front) | Face B (Side) | Face C (Bottom) |

| Pinhole, Glaze Hole, Impurities, Lack of Glaze, Dross, Aluminum Powder, etc. | Not Accepted | Not Accepted | / |

| Different Color Point | 2pcs ≤1mm light color point accepted (per 50x50mm area) | 1pc ≤2mm light color point or 1pc ≤1mm dark color point accepted (per 50x50mm area) | / |

| Pores On Glaze | Not Accepted | Not Dense | / |

| Shallow Glaze, Ripple Glaze | Not Accepted | Not Obvious | / |

| Orange Color Glaze | Not Accepted | Not Obvious | / |

| Sticky Glaze, Burr, Product Stick On Silicon Panel | Not Accepted | Not Accepted | Polish To Be Flat |

| The Producing Body is Uneven, Bubble On Glaze or Other Uneven Factors | Not Accepted | Not Obvious | Repair to Be Flat and Smooth, Not Obvious |

| Crack | Not Accepted | Not Accepted | / |

| Bruise | Not Accepted | Not Obvious | / |

| Size Difference | Standard Size+5cm | ||

| Deformation | Front Straight Edge≤3-4mm, Both Sides≤1mm,Installing Side≤1mm, Against The Wall Side≤1mm | ||

| Warping Angle | Not Accepted | ||

| Holes (for Faucet, Overflow, Drainer) Are Not Round, Not Reasonable | Not Accepted | ||

| The Centerline of Holes (for Faucet, Overflow, Drainer) Is Offset | Not Accepted | ||

| Flowing Glaze Around Holes (for Faucet, Overflow, Drainer) | Polish To Be Flat | ||

Expecting to build a successful brand?

Choose Jabra Sanitary toilet supplier to give you an absolute edge over your

competitors.Jabra Product Testing Protocol

We have our laboratory, equipped with various testers.

We perform 15 tests to produce our top-quality and reliable ceramic toilets.

Out of these, a few are listed below.

Color Difference Tester

Hardware Salt Spray Tester

Yellowing Resistance Tester

Our Quality Standard

With 20 years in the bathroom industry and a focus on R&D, all of our delivered toilets must pass the standard

ISO 9001 International Quality System and the testing standards of CE, cUPC, and ETL certification.

Quality Policy

Jabra Sanitary is dedicated to achieving complete customer satisfaction by:

What We Do

- Ensuring timely delivery of high-quality products.

- Enhancing quality through process control and prevention methods.

- Upgrading manufacturing processes.

- Adhering to governmental and safety standards.

- Continuously improving our quality management system.

Our Goals

- Steadily decrease customer complaints.

- Continually lower product manufacturing costs.

- Regularly reduce rejections, rework, and process discrepancies.

- Enhance product and process efficacy.

Why Choose Jabra

We're your trusted sanitary ware supplier for water closets, flush toilet bowls, smart toilets, or other sanitaryware in China.

Low MOQ

Test 10 pieces to learn customer preferences

High Durability

Test 10 Products endure 500.000 tests longevity

Competitive Price

Prices are 30% lower, with no added markups

Unmatched Efficiency

40% faster delivery than competitors

Reduced Risk

One-stop servlce reduces riskby 60%

Warranty Policy

Two years warranty for non-user faults