English

English

Factory Tour

Factory Strengths

2.2 million

Square ft of Factory Area

20

Production Lines

150 +

Trained Technicians

2M +PCS

Annual Production Capacity

Let's Take a Factory Tour

Production Workshops

Where comfort meets elegance in every detail

Mold Center

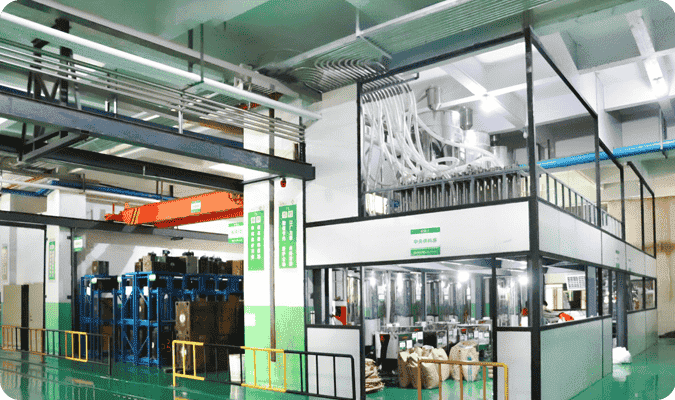

Injection Molding Workshop

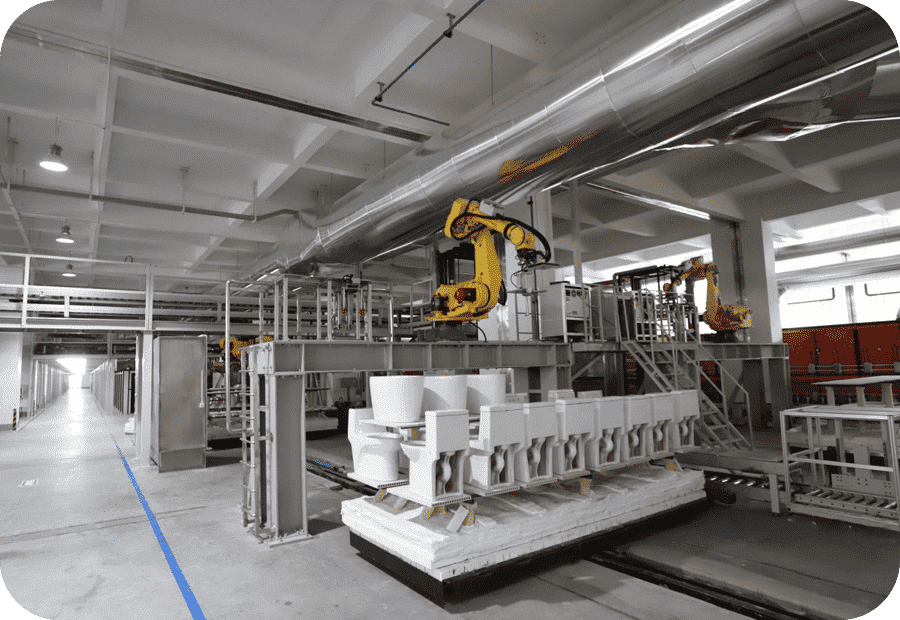

Ceramic Workshop

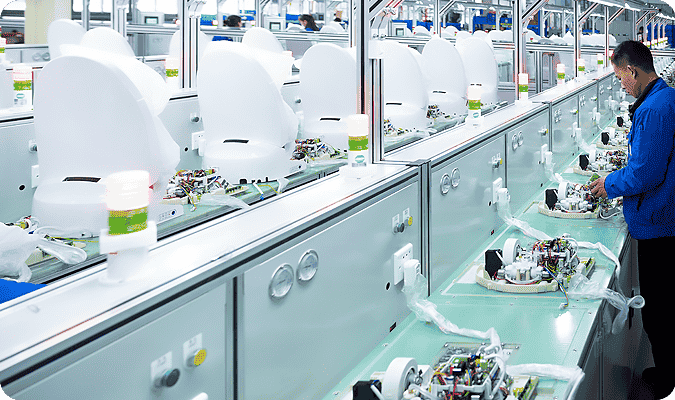

Electronic Assembly Workshop

Mold Center

Molds are an integral part of the injection molding process as they determine the shape and accuracy of

the plastic part.

Looking for a one-stop solution for bulk toilet purchasing?

Tell us your needed quantity and style. We will send you a custom quote for your bathroom project.

Before and After Manufacturing

Excellence in durability, safety, and innovation

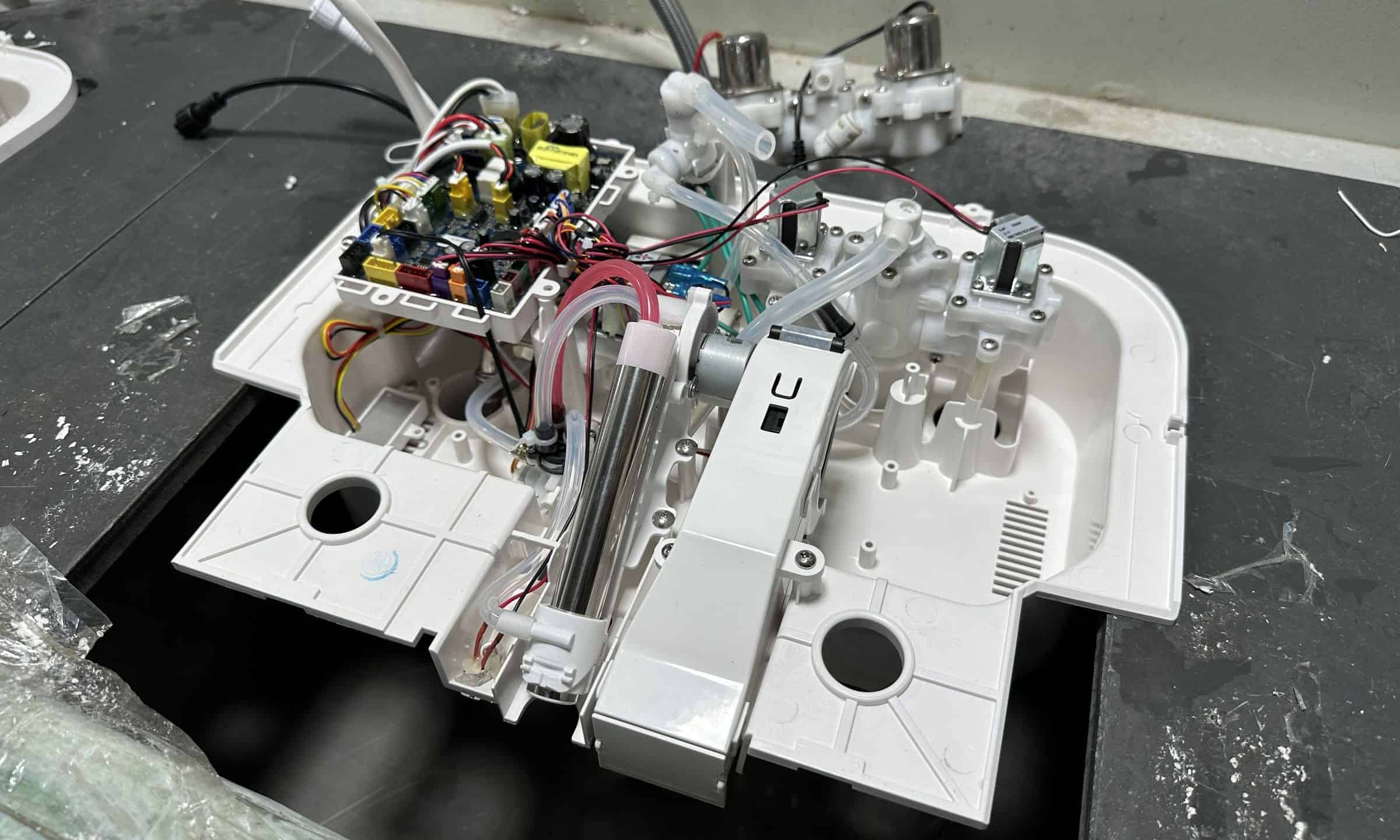

Technology R&D Workshop

Continuously innovate and design

new intelligent functions to meet

the new needs of the market.

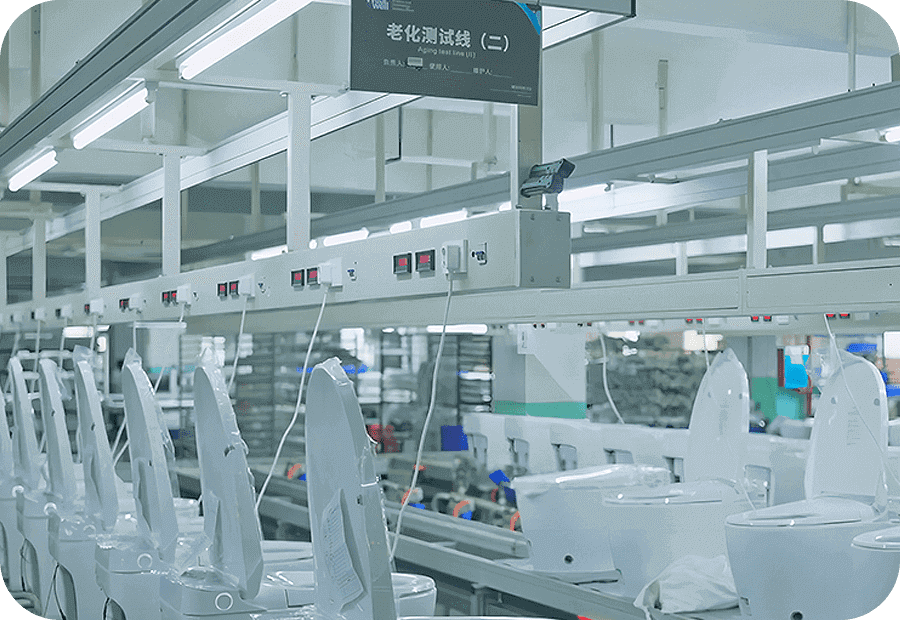

Rigorous Quality Inspection

Functional and safety testing to ensure

that every product meets national standards and undergoes quality inspection

before leaving the factory.

Secure Packaging

Responsible for the final packaging

of products to ensure the safety of

products during transportation.

Advanced shuttle computer kiln

Ensures even and quality firing with precise temperature and time control.

Fully automatic grouting equipment

Automates ceramic slurry injection and molding, enhancing consistency.

Automated rocker arm

Boosts efficiency and safety across production stages.

Automatic glaze spraying

Achieves uniform glaze quickly and efficiently.

How We Keep a High Level of Efficiency

Guarantee fast delivery

We annually produce over 2 million top-quality

sanitary wares, reinforcing Jabra Sanitary's global

market leadership daily.

The close and smooth cooperation of our workshops

ensures that the quality and performance of our

sanitary products are at their best.

Our Professional Team

Driven by passion, delivering top-notch, innovative products.

1 Research and Development (R&D) Team

We have over 50 engineers and designers in the R&D team which focuses on developing products that align with market needs and technological trends.

They have a strong innovation capability with numerous patents and design awards.

3 Sales Team with 20 Years of Experience

We operate three specialized sales teams catering to retail, engineering, and wholesale sectors. Each team includes international sales representatives and sales managers.

With over 20 years in foreign trade, they are good at managing every step from order to delivery efficiently.

1 Customer Service Team

Customer satisfaction is crucial at Jabra Sanitary.

Our experienced customer service team with dozens of members offers prompt, effective solutions regarding product consultations, resolving issues, and providing after-sales services.

1 Quality Assurance (QA) Team

Jabra Sanitary's quality control team consists of ten members of quality engineers, inspectors, and lab technicians.

With stringent quality control processes and advanced testing equipment, the QA team ensures product quality at every stage, from raw materials to finished products.

They do their best to ensure every product meets strict international standards and reduces the risk of flaws.